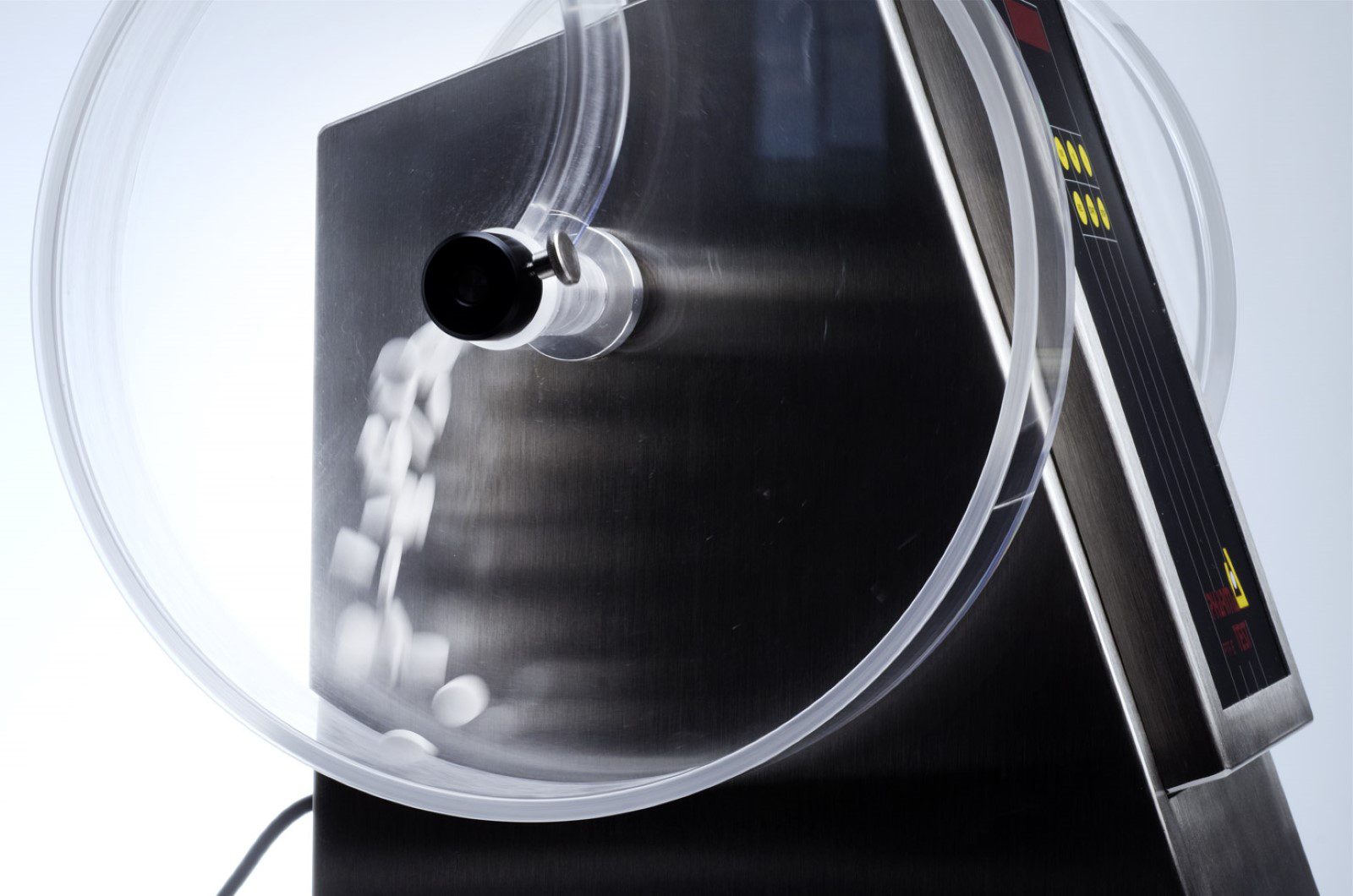

The PTF 20E and PTF 20ER are double-drum instruments, fixed or variable speed tablet friability test Instruments are manufactured in compliance to the USP [1216], EP [2.9.7] and other Pharmacopoeias. Both versions are available as single or dual drum instruments.

PTF 20E/ER double-drum Tablet Friability Test Instrument

General Information

One of the testing criteria of mechanical strength of tablets and cores is friability and abrasion testing. During the process of coating, transportation and packing the tablet will lose some amount of weight. To measure the weight loss, the samples are counted and weighed. Then the friability test is performed following the individual monographs of the relevant Pharmacopoeia. The tablets are tumbled at each turn of the drum of the friability testing instrument by a curved projection that extends from the middle of the drum to the outer wall. Once the friability test is finished, the samples have to be de-dusted and weighed again. The weight difference before and after the test is determined as friability; this usually should not exceed 1%. Tablets of a weight >650mg or with a bigger diameter or odd shaped samples are tested while the instrument is raised on one side using collapsible feet to an angle of 10%.

Different Speed Settings

A silent DC geared motor rotates the drums at a fixed speed of 25 rpm (PTF E) or variable speed (PTF ER). The actual drum is made from Plexiglas (Perspex) and is separated into two parts, the drum body and a removable cover, which opens to fill, discharge and clean the drum from the inside when required. The instrument itself is made from high quality stainless steel which fully meets the current GLP requirements. An anti-static coated friability drum is available as an option.

Principle of Operation

The PTF E instruments operate at a fixed speed setting of 25 drum rotations per minute and are available with either one drum (PTF 10E) or two drum (PTF 20E). The PTF ER instruments feature a variable speed setting between 20 and 70 rpm and are also available with either one drum (PTF 10ER) or two drums (PTF 20ER).

Clean the samples from any dust prior to the test. Weigh the samples and introduce them into any drum of the instrument. Program the test information, such as speed, time etc. and start the run. When the test is finished the drum revolution stops and the samples have to be discharged. De-dust the samples using a brush and weigh them again. The maximum mean weight loss from 3 consequent tests should not exceed 1%.

Technical Specifications

| Parameter |

Specification |

| Display |

LED Display |

| Data Entry |

Functional Keys |

| Setting number of revolutions |

1 to 9999 |

| Setting rotation timer |

1 to 9999 seconds |

| Drum rotation speed

PTF 10E/20E |

Fixed to 25 rpm

Accuracy ± 1 rpm |

| PTF 10ER/20ER |

Adjustable speed between 20 - 70 rpm

Accuracy at 20 - 30 rpm ± 1 rpm, > 30 rpm ± 2 rpm |

| Bench Space Requirement |

W 350.0 x D 400.0 mm |

| Certification |

All components certified to USP / EP requirements |

| CE / EMC Certification |

All CE / EMC Certification provided |

| Validation |

All IQ & OQ documents included |

We reserve the right to make technical changes without any prior notice.