The PTWS 1420 is a 14+2-position, "dual drive" compact tablet dissolution testing instrument for solid dosage forms as described in USP chapter [711/724] and EP section[2.9.3/4] as well as the BP, DAB and Japanese Pharmacopeia section [15]. The instrument features 14 testing positions and includes two additional standard size vessels for media refilling and reference standard media. PTWS 1420 features independent stirrer speed control for the left and right half of stirrers.

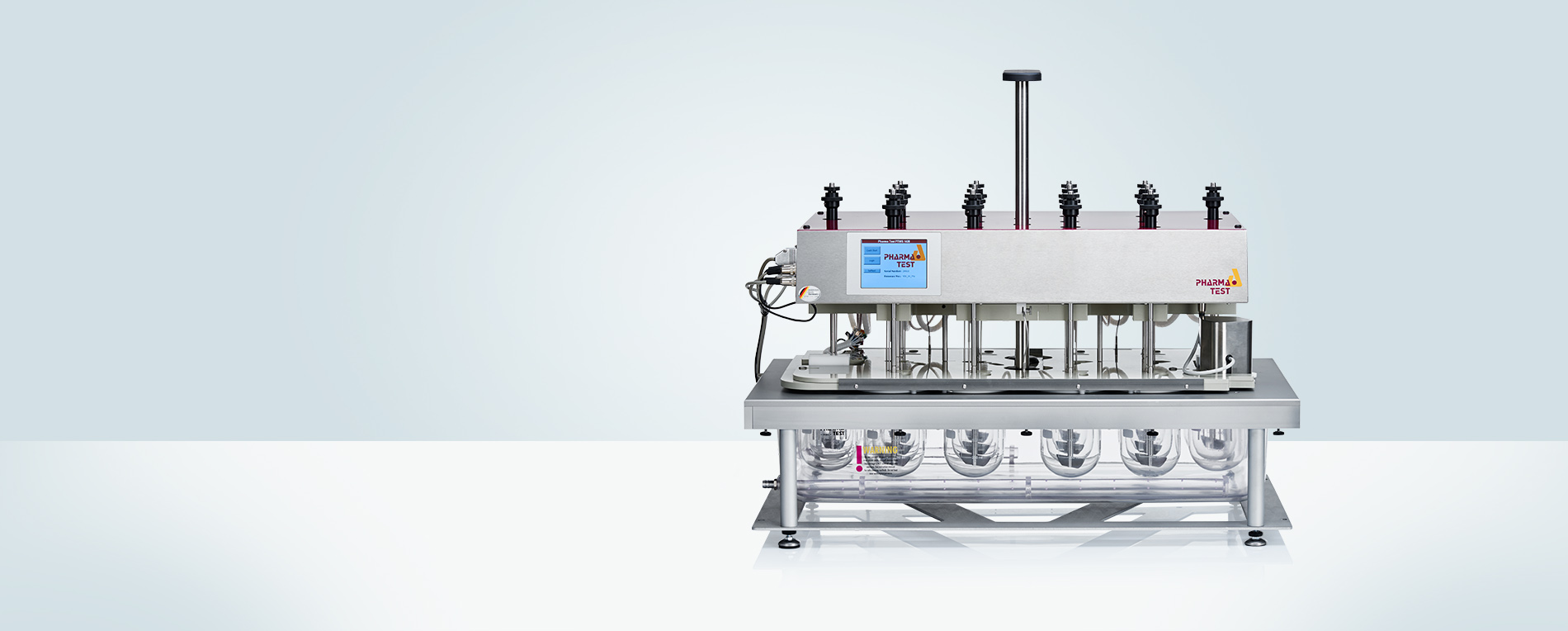

PTWS 1420 USP/EP Tablet Dissolution Testing Instrument Front View

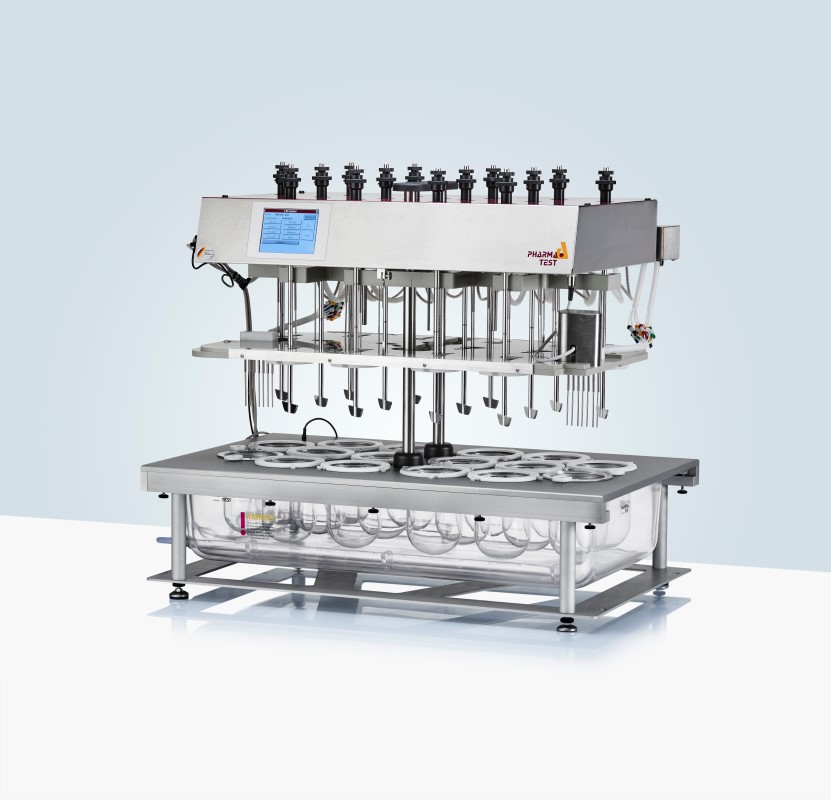

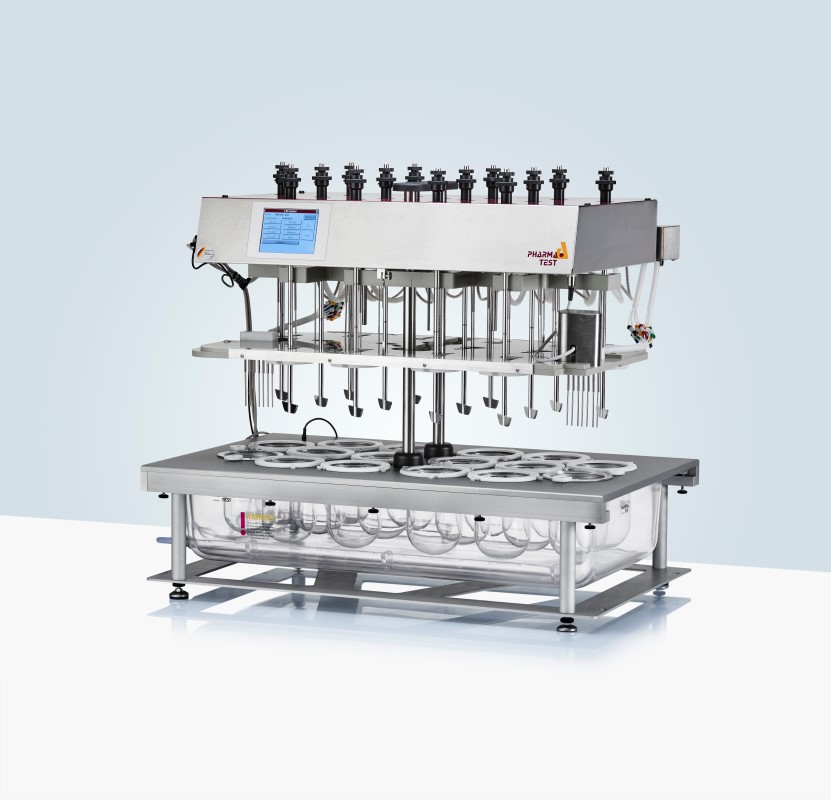

PTWS 1420 USP/EP Tablet Dissolution Testing Instrument Side View

Previous

Next

Perfect Biowaiver Solution

PTWS 1420 is the first tablet dissolution testing instrument from Pharma Test featuring 14 full size stirred vessel positions. The vessels are arranged in a two times 6+1 configuration. This way not only your samples but also the standard or reference media will be heated and stirred by the instrument. In addition PTWS 1420 features two additional heated full size vessels to store the replacement media for systems including an auto sampler. This way also the replacement media, which is filled into the vessels after sampling, always has the same temperature as the test media – eliminating any influence on the dissolution test due to the refilling of cold media. The 14+2 vessel design of PTWS 1420 makes this instrument an excellent choice for Biowaiver applications and offline automated systems.

Password Controlled

Access to the instrument can be password controlled if required. If certain operational parameters form a regular feature of the daily routine, then these can be incorporated into a test method for faster set up. These parameters can be tool speed, target bath temperature, sampling time points and so on. The test method memory capacity is almost limitless. As soon as the test is started, a screen saver can be activated with the most important information displayed in large script so that this information remains visible even at time when the operator is not standing directly in front of the instrument.

User Interface

In keeping with our cutting edge design, a large color, touch screen allows control of the various mechanical features of the instrument such as the tool stirring speed, lift drive and heater. The instrument control is menu driven using a resistive touch screen and selection wheel technology. Visual signals on the display inform the user of the status of critical instrument parameters, e.g. bath target temperature not reached. Access to the instrument can be password controlled if required.

As soon as the test is started, a screen saver can be activated with the most important information displayed in large script, like count-down timer so that this information remains visible even at time when the operator is not standing directly in front of the instrument.

Stirring Tools

The PTWS 1420 uses the Pharma Test MonoShaftâ„¢ design. Tools consist of the main shaft plus interchangeable tool heads (adapters). The main shaft remains in place in the instrument regardless of the tool head being used. The clearance of each tool from the vessel base will always be correct once the main tool shaft has been installed and qualified with any one of the tool sets once. Each stirrer can be raised by hand into a convenient position for easy vessel removal or insertion. PTWS 1420 is capable to perform a staggered start for each of the 14 testing positions, which is essential in manual operation.

PTWS 1420 in raised position