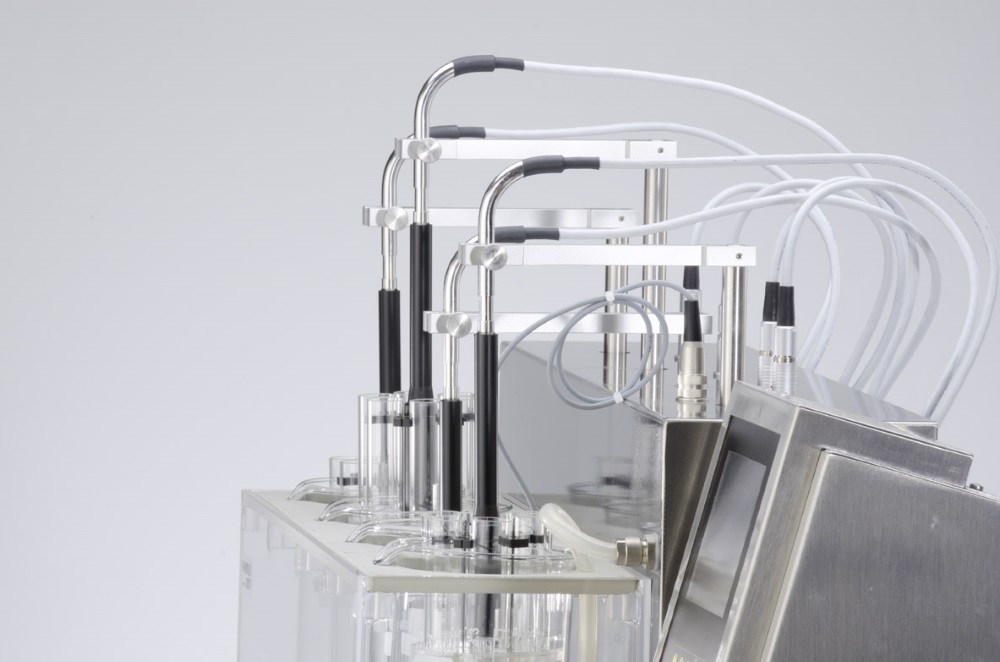

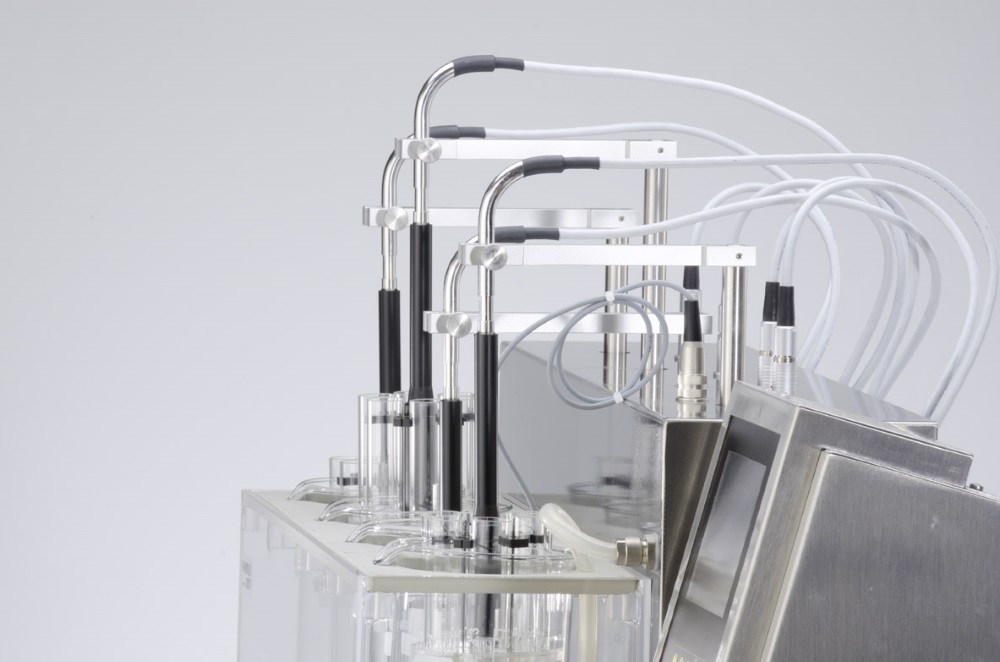

The fully automated PTZ AUTO EZ instruments are available as 1, 2, 3 or 4 station models. The instruments are automatically detect the individual disintegration times of tablets and other solid dosage forms. Each automated disintegration basket can be operated independently. They are equipped in full compliance with the USP[701/2040] and EP[2.9.1/2.9.1.2] pharmacopoeia requirements.

Operating Mode

A large LCD screen and an alpha-numerical keyboard are used to edit product and test information, such as the target disintegration time for each station and the bath and media temperatures. Up to 16 different testing methods can be filed in the instrument's memory.

The instruments are supplied with a complete PT-MKT electronic disintegration test basket for each testing position. Each basket is used to test six samples and includes six glass tubes and six disks. For larger samples of up to 30mm diameter we offer the PT-MKT33 basket ("B"-type according to USP [2040] and EP [2.9.1.2]). This basket is used to test three samples and is equipped with three tubes and disks only.

To enable the automated detection of the final disintegration time of each individual sample, the basket bottom sieves are split. A small metal ring is injected into the disks during manufacturing. This ring closes a contact between the two sieve halves once the sample has disintegrated. Each disk can be used in any of the testing positions. There is no need to place them always into the same tube or even basket. There is also no need to use different designs or tools to test different tablet shapes. The complete basket designs including sieve and disks are in compliance with the current USP and EP pharmacopoeias. The specific weight of the disks is kept in full compliance too.

Sustained Release Testing

At the end of a test run, each basket is completely raised out of the test media by the individual basket lifting system. This feature is particularly useful if sustained released products are tested, which may require a medium change during the test run.

Available disintegration basket types: PT-MKT basket, standard basket, 3-position standard basket and PT-MKT33 basket (left to right)

The PT-MKT basket has a split sieve on the bottom

The disintegration disks feature a metal ring to close the contact between the sieve halves

Each PT-MKT basket includes a temperature sensor to monitor the medium temperature

Previous

Next

MKT Baskets

The electronic disintegration baskets PT-MKT or PT-MKT33 are equipped with a temperature sensor to monitor the actual media temperature inside the glass beaker during operation. The disintegration time of each individual tablet within the basket is automatically detected. The total time is recorded and displayed. The printed report shows the individual disintegration time of each sample, minimum and maximum time, as well as mean value and standard deviation of all 6 or 3 samples.

The report includes the system information of bath and media temperature with no need of any external computer or software. Simply connect any suitable PCL printer to the parallel printer port of the PTZ AUTO EZ to receive your result report.

Heating System and Mechanical Features

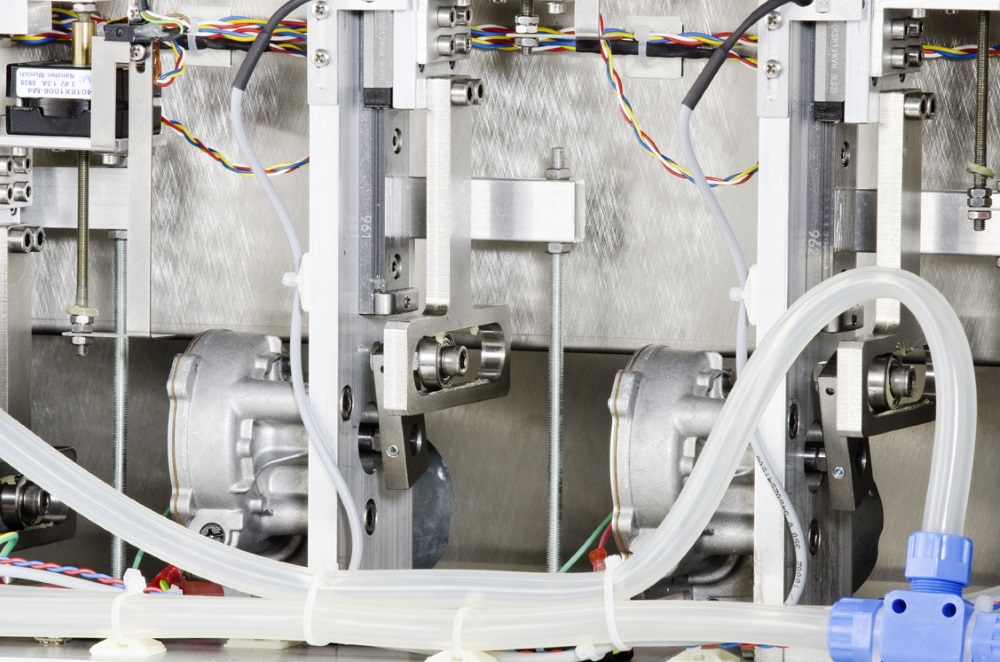

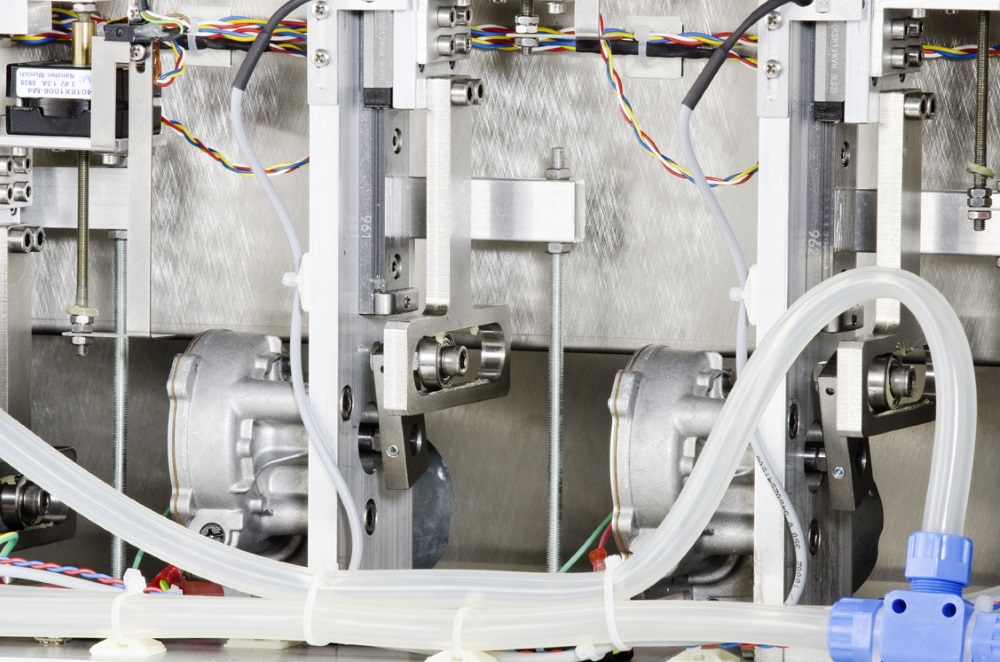

The built-in heating system of the PTZ AUTO EZ instrument uses a silent circulation pump and a heater to pre-heat the outer water and keep the temperature within a tight tolerance. The actual bath temperature is displayed at all times and measured by an external movable temperature probe inside the water bath. The overheating protection system includes a pressure gauge to monitor the pump flow, a thermo switch and thermo fuse to cut the power supply in case of an electronical fault.

This secures automatic shutdown of the pump and heater in the event that no water flow is detected or the electronical control system fails. A built-in digital safety sensor placed at the end of the heating coil shuts down the heating when temperature exceeds +60˚ C max. 95˚ C at the heater.

Cleaning and Maintenance

For easy cleaning and maintenance, the Plexiglas water bath can be removed quickly. Fast tube couplings connect the tubing to the heating system. The digital controlled stroke mechanism is automatically adjusted to provide the USP / EP specified 30 strokes a minute to each station.

Use 6-position PT-MKT and 3-position PT-MKT33 baskets in the same system and change on the fly

Each testing station can be operated and started independently

Each station features a dedicated motor drive and an automated basket lift up system that raises the basket out of the medium at the end of a test

Previous

Next

PTZ32 Software

The PTZ AUTO EZ is equipped with a serial RS-232 interface. The instrument can be connected to a PC and the PTZ32 software (21 CFR part 11 compliant) offers test methods, result filing, batch comparison and graphical information. Export functions to Excel and LIMS (Laboratory Information Management Systems) are available as options.